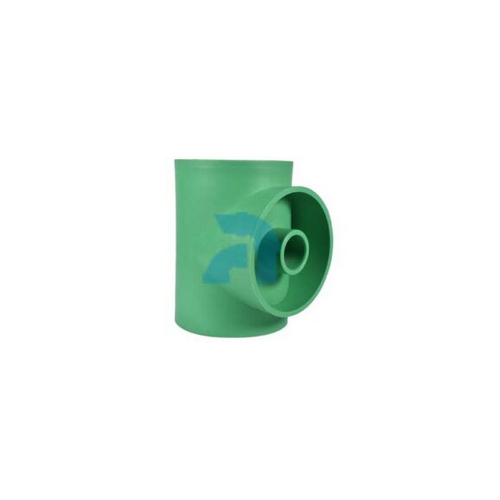

PPR Pipe Fitting

1000 INR/Piece

Product Details:

- Product Type Coupling

- Material Other

- Surface Treatment Galvanized

- Color Green

- Click to View more

X

PPR Pipe Fitting Price And Quantity

- 1 Piece

- 1000 INR/Piece

PPR Pipe Fitting Product Specifications

- Other

- Green

- Galvanized

- Coupling

PPR Pipe Fitting Trade Information

- 7 Days

- West India

Product Description

We are a reputed entity, engaged in manufacturing and supplying a qualitative array of PPR Pipe Fitting.Specifications:

- Material: Polypropylene random copolymer

PPR Pipe Fitting:

PPR a versatile, and comprehensive system for water and other fluid delivery, is used in applications of pressurized warm or cold water in all modern residential, commercial, and industrial applications.

Why PPR?

- Exceptional corrosion & erosion resistance

- High chemical resistance

- Low Thermal Conductivity

- Anti -Fungal & Non-toxic

- Leak -proof & airtight homogeneous joints

- Negligible head loss, Minimum Pressure loss & Higher flow Rate

- Inherited characteristic of high impact strength

- Wide Temperature range: -4C to +95C lottery low thermal loss

- Trouble -free installation process & light in weight gong Service life

- Highly economical

- Superior Impact, Fracture Resistance & Minimum Crack Transmission

- PPR being an Eco-Friendly product does not catches fire straightforwardly, indeed in case of fire it doesn't produce toxic gases

PPR An Ideal Solution:

PPR pipes and fittings are designed to withstand constant temperatures up to 70C. The service life expectancy depends on the installed system pressure and pressure changes. Even though the service fife expectancy of the pipes is more than 50 years, a permanent temperature rise from 70C to 90C will accordingly reduce the operational life of the pipe. However, a temperature rise up to 100C in short time frames is usually unproblematic.

Fusing tool:

The pipes and fittings in Type three PP -RC piping systems are connected through thermal fuse plugging, the thermal fusing tools are applied to melt the inner & outer surfaces of the fitting and pipes simultaneously and plug connect them under the specified temperature and conditions. the two pats are integrated uniformly and firmly when cooled. The connection provides good searing, high reliability and avoids any leakage. See the table for fusing connection technical requirement.

Installation technical precautions:

- When temperature drops under 0C in winter, precaution must taken to prevent possible cracking of pipes if the pipes are hit by external force.

- The pipe shall be away from heat when stored for long time, direct sunshine shall be Avoided during product transportation or storage.

- PP -14C pipe has big expansion coefficient, technical measures must be taken to prevent the thermal deformation of the pipes during the exposed or covered pipe layout.

- One support or hanger (pipe buckle seat) must be installed every 400mm in exposed layout or non-linear covered layout.

- During installation, relevant design & installation codes must be followed, the construction workers must be trained and carry their certification badges at work.

| Size/ Diameter | 20mm-315mm |

| Fitting Type | socket fusion |

| Usage/ Application | Chemical |

| Application | Gas Pipe, Chemical Fertilizer Pipe, Pneumatic Connections |

| Size | 1/2 inch |

Enter Buying Requirement Details

Send Inquiry

Send Inquiry Send SMS

Send SMS